44 workplace labels must be put in place

Pictogram requirements for product labels under the revised Hazard ... Under paragraph (f) (l), each container of hazardous chemicals leaving the workplace must be labeled, tagged, or marked with the information specified in section 1910.1200 (f) (l) (i)- (vi). The requirement to label a shipped container has not changed under the Hazard Communication Standard (HCS). The information required on the label has changed. Workplace Safety Procedures - Workplace Safety in the Foodservice Industry Particular care must be taken when cleaning the slicing machine. First pull the plug. Turn the gauge to zero in order to cover the edge of the blade Do not touch the edge of the blade Clean the blade from the centre out. Clean the inside edge of the blade with a stick that has a cloth wrapped around one end.

WorkSafeBC (b) the health and safety of persons at the workplace is not put at risk by compliance by only one person. Section 3.1 of the Regulation states: 3.1 When program required (1) An occupational health and safety program as outlined in section 3.3 must be initiated and maintained (a) by each employer that has (i) a workforce of 20 or more workers, and

Workplace labels must be put in place

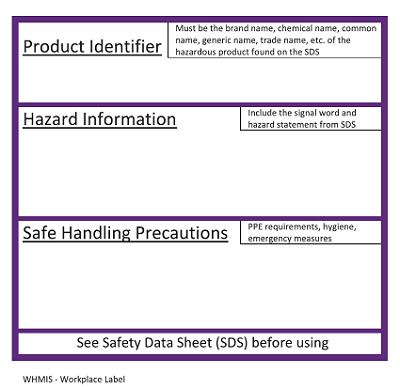

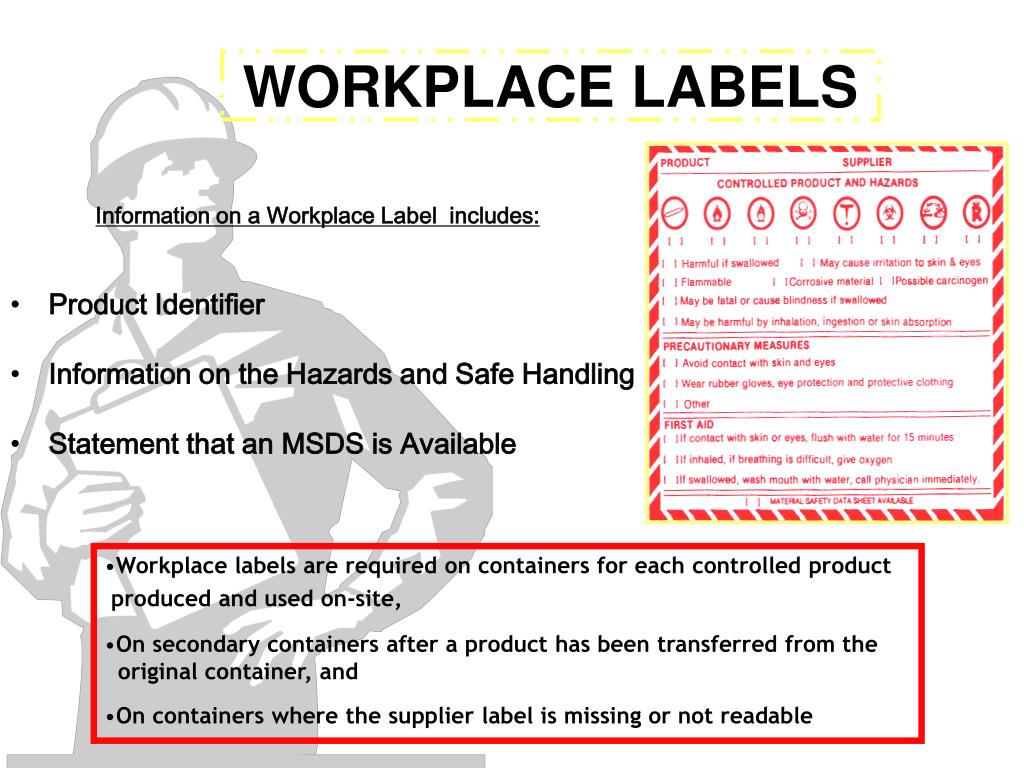

4.7 - Workplace labels | WHMIS 2015 - University of Ottawa created in the workplace, received without a supplier label or transferred into a container that had no labelling. Workplace labels do not require a border or specific wording; they do, however, require the following information: Product identifier (product name matching that on the SDS), Information for the safe handling of the product, and Five Ways to Meet OSHA Requirements for Safety Signage 1) Understand ANSI and OSHA Requirements for Signage. 29 CFR 1910.145, OSHA's guideline for signs and tags that identify hazards, outlines design requirements and specifies when safety signs must be used. These design elements are expanded upon in the ANSI Z535 standard, which utilizes alert symbols and pictograms to communicate hazards. 11 Rules for Safe Handling of Hazardous Materials Rule #9. Store all materials properly, separate incompatibles, and store in ventilated, dry, cool areas. Rule #10. Keep you and your work area clean. After handling any material, wash thoroughly with soap and water. Clean work surfaces at least once a shift so that contamination risks are minimized. Rule #11.

Workplace labels must be put in place. Container Labeling: A Key to Compliance -- Occupational Health & Safety After deciding on a format for labeling, employers should designate someone with the responsibility of ensuring containers are properly labeled, information on labels is reviewed periodically, and... Workplace Label - WorkSafeBC WorkSafeBC WHMIS 2015: The Workplace Label The workplace label is one of the two main types of WHMIS labels. This toolbox meeting guide discusses when workplace labels are needed, the information they need to show, and the formatting guidelines for these labels. This guide also describes two specific cases in which workplace labels are not needed. Mandatory OSHA Posters and Signs - Safety Blog - Safesite OSHA regulates most workplaces and requires safety signs at most locations where a hazard threatens the safety of a worker. Each safety sign is classified by hazard risk to help determine what sign to use, including DANGER, WARNING, and CAUTION. Implement these key safety sign formats to meet OSHA requirements for safety signage. DANGER Workplace Hazardous Materials Information System (WHMIS) Employers must ensure that workers are trained on products compliant with WHMIS 1988 requirements for as long as they are still used in the workplace and on hazardous products with WHMIS 2015 labels and safety data sheets as soon as practicable after they enter the workplace (and, in some cases, before they are used). The type and

Compliance FAQs: Packaging and Labeling in the US | NIST title 19, united states code, chapter 4, section 1304 and 19 cfr 134, country of origin marking regulations require that every article of foreign origin (or its container) imported into the u.s. be marked in a conspicuous place as legibly, indelibly, and permanently as the nature of the article (or container) will permit, and in such a manner as … Intro to Hazard Communication, Part Three: Labeling Requirements If you consistently work with specific chemicals in your operations and place them in workplace containers, you can buy secondary containers from certain industrial supply stores that come with pre-affixed labels containing the chemical name and other hazard communication elements, such as pictograms. PDF GUIDE FOR EMPLOYERS AND WORKERS Workplace Labels - WSCC 4REFERENCE TO SDS If available. GENERAL LABELLING REQUIREMENTS Convey workplace labels in a manner that is appropriate to the workplace, including meeting language requirements. Labels must be easy to read and durable. If the label is lost, damaged, or no longer readable, the product must be relabelled. WHMIS 2015 - Labels : OSH Answers A workplace label is required when: a hazardous product is produced (made) at the workplace and used in that workplace, a hazardous product is decanted (e.g., transferred or poured) into another container, or a supplier label becomes lost or illegible (unreadable). There are two situations when a workplace label is not necessary.

Safe use of machinery | WorkSafe HSE Regulation 17 requires employers to make sure machinery is safe to clean, maintain and repair. Procedures must be put in place for these activities to be performed safely and workers must be trained to follow them. Isolation, tag out cards and lock-out devices should also be used as described in section 8.1.11 of this guideline. Anesthetic Gases: Guidelines for Workplace Exposures Jul 20, 1999 · Labels must be legible, in English (plus other languages if desired), and prominently displayed. Each MSDS must be in English, although the employer may maintain copies in other languages as well, and must include information regarding the specific chemical identity of the anesthetic gases or hazardous chemical and its common names. Workplace Posters | U.S. Department of Labor - DOL Workplace Posters Some of the statutes and regulations enforced by the Wage and Hour Division (WHD) require that posters or notices be posted in the workplace. Please note that posting requirements vary by statute; that is, not all employers are covered by each of the statutes administered by the WHD and thus may not be required to post a ... Roles and Responsibilities – Workplace Safety in the ... You must make sure that there are safe entrances to and exits from the workplace. You must make sure that the work area is safe for the movement of workers, equipment, and materials. You must wear protective eyewear when using grinders and other equipment that may be hazardous to the eyes. Health and Safety Committees

Proper Labeling Chemical Containers - OSHA Review The secondary label must include product identifier and words, pictures, symbols, or combination thereof, which provide at least general information regarding the hazards of the chemicals, and which will provide employees with specific information regarding the hazards of the chemicals.

10 Reasons Why Industrial Labeling is Important | Creative Safety ... 1. Regulatory Compliance. One of the most important reasons why you need to focus on proper industrial labeling is that it is often required by organizations like OSHA. If you are using certain hazardous chemicals, for example, you will need to have the containers labeled using the proper industry standards.

WHMIS 1988 - Labelling Requirements : OSH Answers "Where, in a work place, a label applied to a controlled product or a container of a controlled product becomes illegible or is removed from the controlled product or the container, the employer shall replace the label with a work place label that discloses the following information in respect of the controlled product (a) the product identifier;

GHS Labeling Requirements: The Definitive Guide [2021 Update ... - Luminer However, the GHS takes into consideration that, sometimes, it's not possible to keep workers safe with only these six label requirements, which is why it also allows for supplemental information. 1. Product Identifier. This requirement identifies the actual hazardous chemical inside the container.

WHMIS Workplace Labeling - Environmental Health & Safety A workplace label is not required if the worker who transferred the hazardous chemical will use up the chemical on the same day it was transferred. Non-hazardous chemicals do not require a workplace label. Salt solutions, phosphate buffers and broths would typically not be considered hazardous, and therefore would not require a workplace label.

Safety Signage And Your Workplace. - WHS Consulting The purpose of having safety signage in the workplace is to identify and warn workers who may be exposed to hazards in the workplace. Safety signs can assist in the communication of important instructions, reinforce safety messages and provide instruction for emergency situations. Workplaces have an obligation under Health & Safety Legislation ...

Your arc flash labels must comply with NFPA 70E standard 2015 In Article 130.7 (E) (1), the NFPA 70E standard further notes that the design and formatting of the labels should conform with ANSI Z535 Series of Standards For Safety Signs & Tags. Thus it is recommended that the header, message and pictogram, if used, be formatted according to ANSI standards. Currently there is not a widely-accepted symbol ...

Labeling of Secondary Containers - Occupational Safety and Health ... section 1910.1200 (f) (6) (ii) requires that workplace labeling include "product identifier and words, pictures, symbols, or combination thereof, which provide at least general information regarding the hazards of the chemicals, and which, in conjunction with the other information immediately available to employees under the hazard communication …

Top 10 Safety Rules in the Workplace Wear suitable personal protective equipment - This will help to protect you from workplace injuries and accidents. Safety boots must be used in workshops. Safety glasses are required to protect your eyes in job sites. Keep your workplace clean and tidy - Store tools, equipment, and supplies should be kept properly when not in use.

Safety Signs and Labels - OSHA Compliant and Specifications - SafetyInfo The message and safety symbols should be printed in green or black on a white background. The signs may also be printed in white on a green background. These signs should never include the safety alert symbol. Fire Safety signs are used to indicate the location of emergency fire fighting equipment. Unlike other signs, they do not require a header.

PDF Workplace Labeling Requirements - Concordia University There are four (4) situations when workplace labels are required: 1. A hazardous product is produced (i.e., synthesized or prepared) and will be used on-site by several individuals and will be stored for a long period of time or will leave the workplace. It must be stocked in a suitable (chemically compatible) container.

Workplace Safety Signs [OSHA + ANSI Compliant] | Creative ... Whatever dangers your workplace has, you can likely find a safety sign or create a custom version that meets OSHA guidelines. Other safety signs direct people to first aid equipment, fire-fighting equipment, and other important locations. Businesses must mark these items, as they are critical when responding to an emergency.

Arc Flash Labeling Requirements | Comply with 2021 NFPA 70E The recent update allows labels applied prior to the effective date of this edition of the standard to be acceptable if they complied with the requirements for equipment labeling in the standard in effect at the time the labels were applied (unless changes in electrical distribution system render the label inaccurate). Document and Review ...

Labeling Requirements | US EPA The label on a pesticide package or container and the accompanying instructions are a key part of pesticide regulation. The label provides critical information about how to handle and safely use the pesticide product and avoid harm to human health and the environment. Labeling Requirement Resources

Putting the Right Signs in the Right Places - Occupational Health & Safety Consider these commonly used labels and signs: Pipe markers Equipment marking Tank and vessel signs Right-To-Know labels Lockout/tagout labels and tags Aisle and floor marking Safety...

Information Elements Required on a WHMIS 2015 Label - Canada Supplier labels must be both English and French, durable and legible without the aid of any devices other than corrective lenses. If the label of a hazardous product is lost, damaged, or no longer readable, the product must be relabelled before it is sold or upon its importation into Canada.

![Top 5 Workplace Etiquette Breaches in an Open Office Space [Infographic]](https://infographicjournal.com/wp-content/uploads/2014/09/Workplace_Etiquette.jpg)

CON workplace label product image EDIT.jpg?width=1024&name=PREempt (USA) CON workplace label product image EDIT.jpg)

Post a Comment for "44 workplace labels must be put in place"